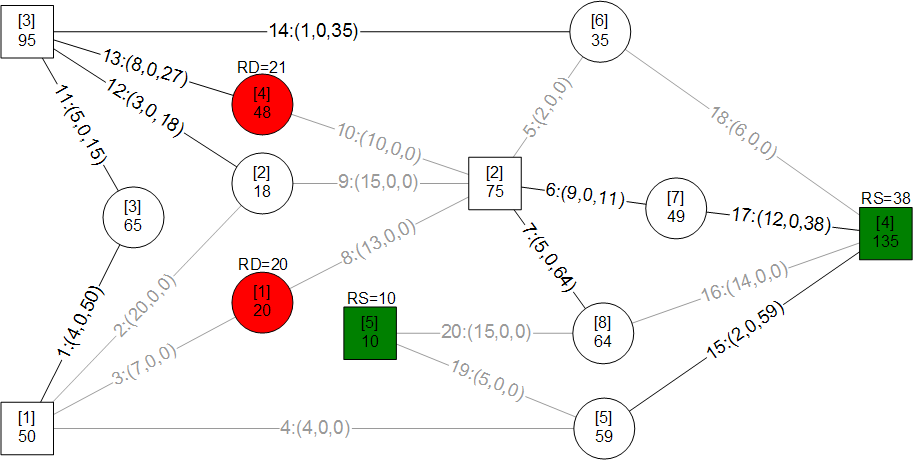

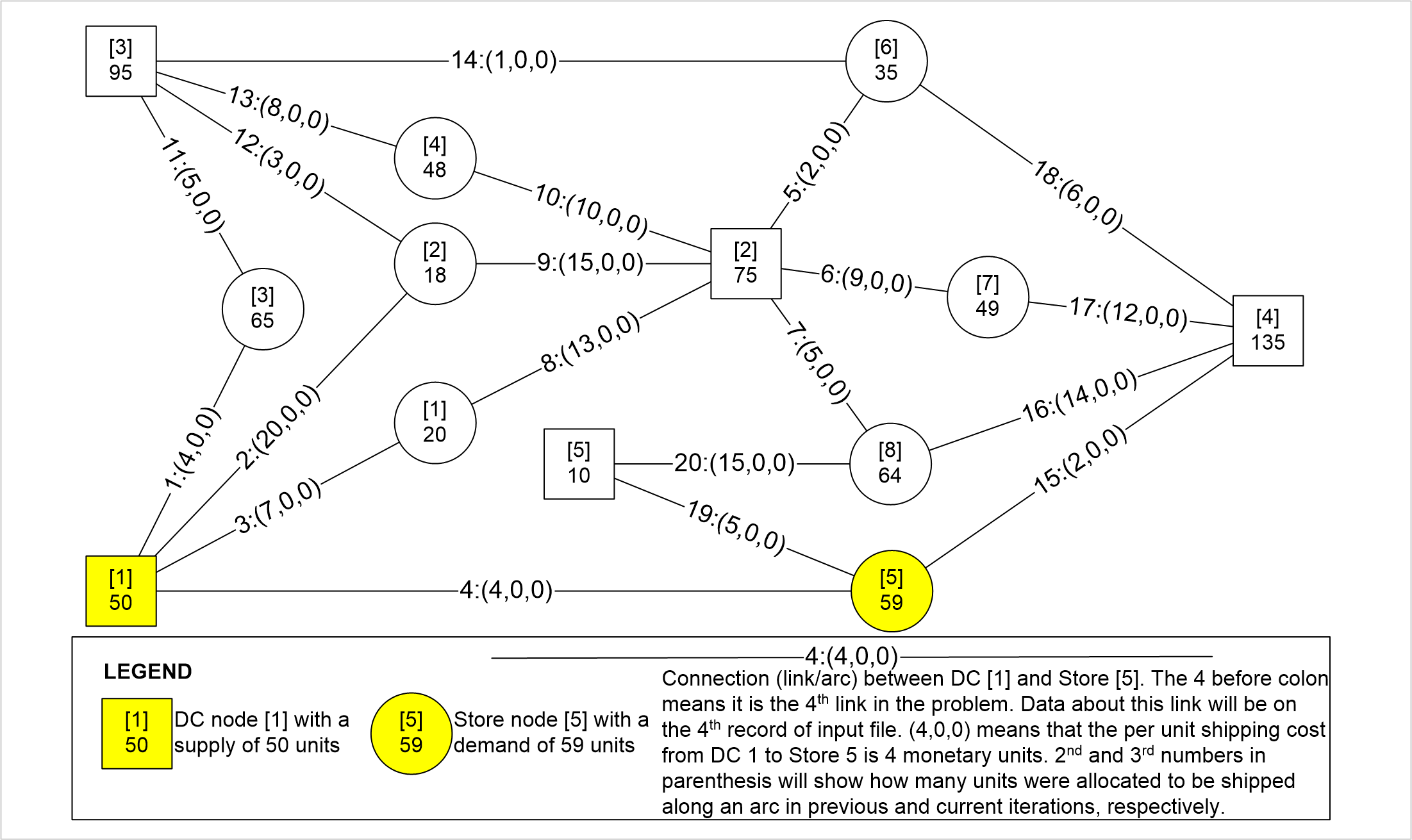

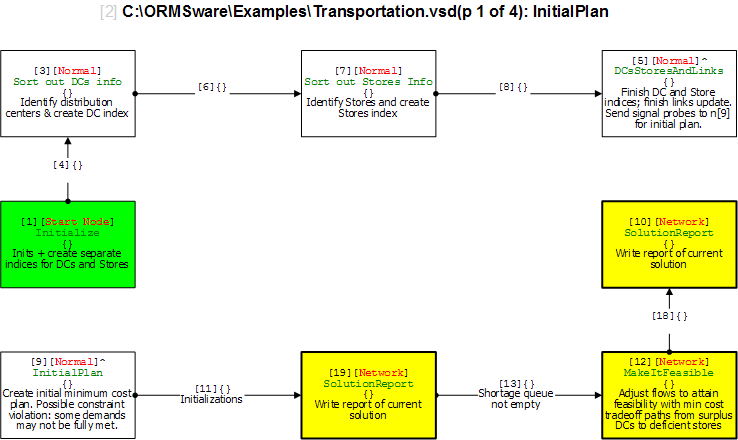

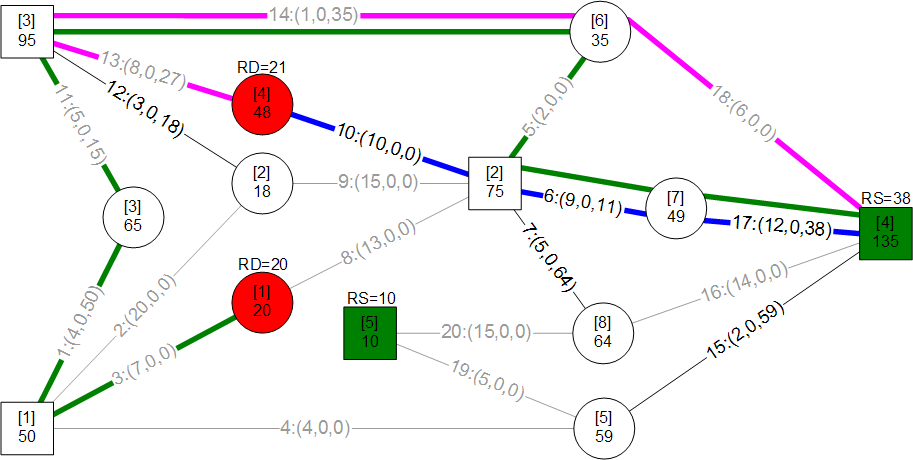

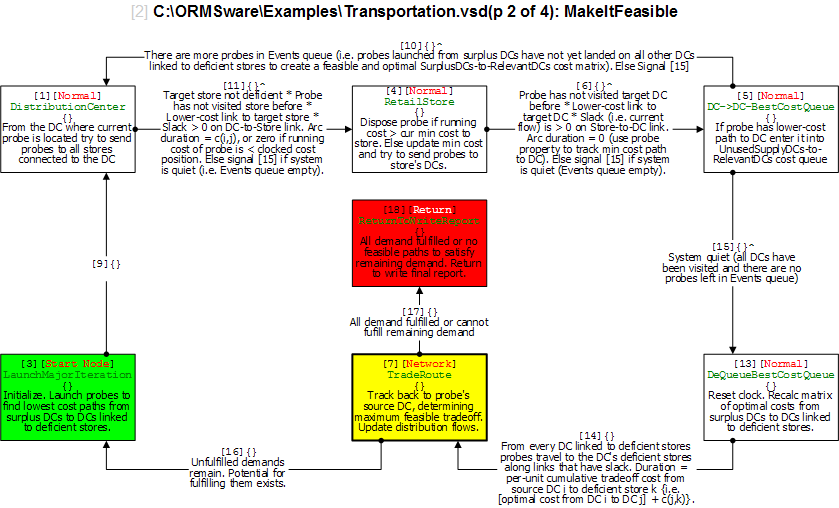

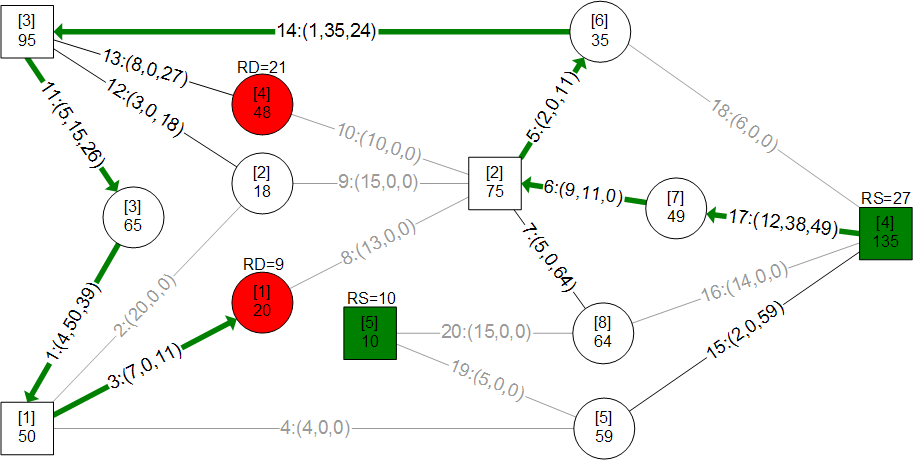

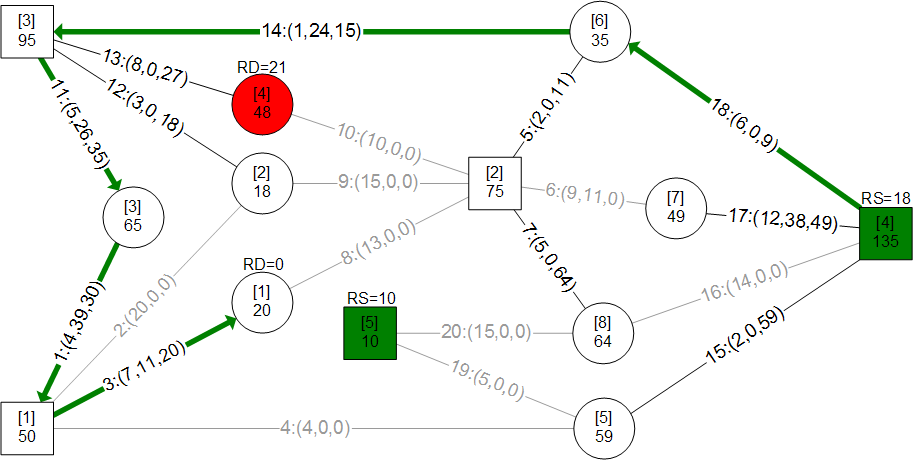

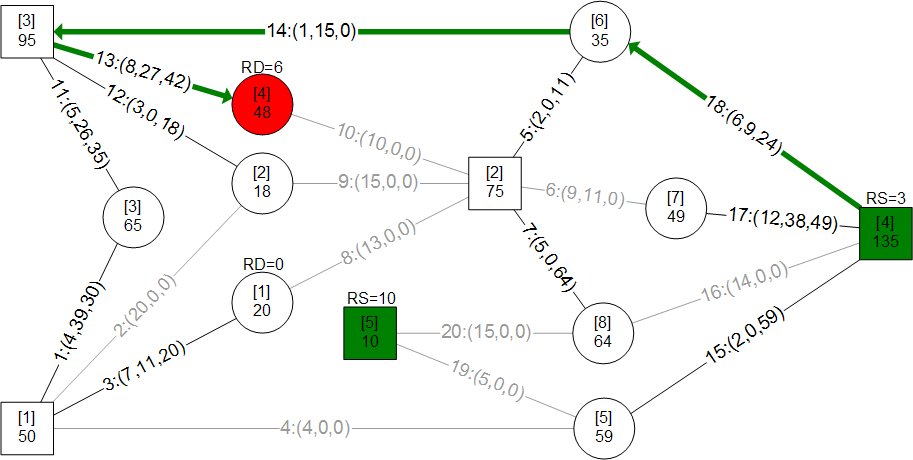

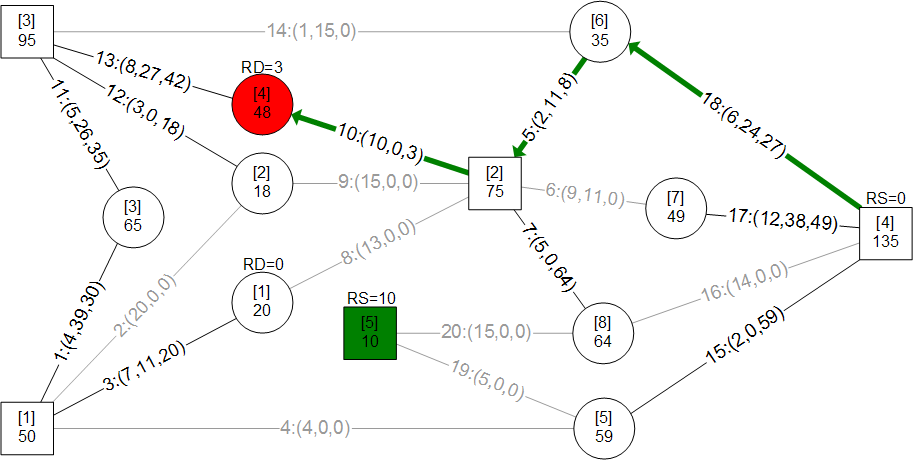

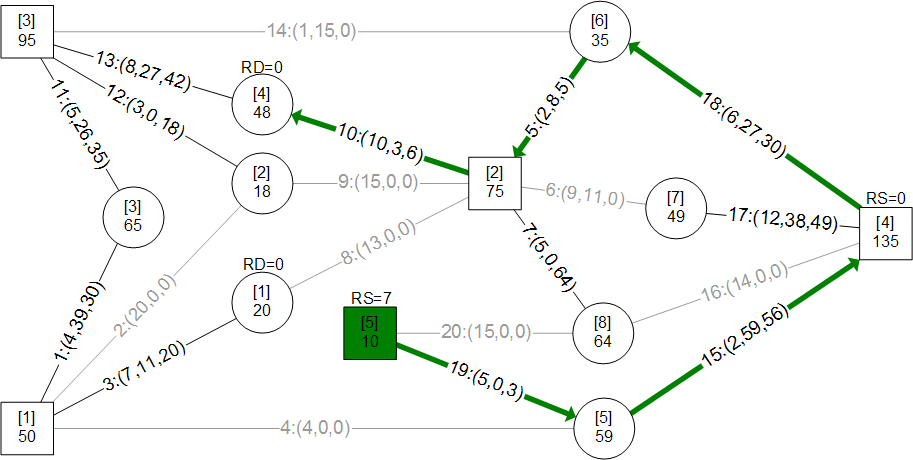

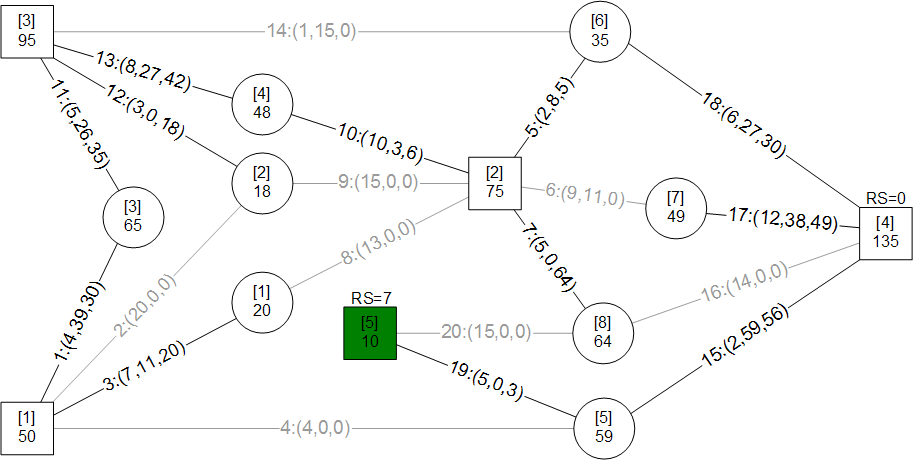

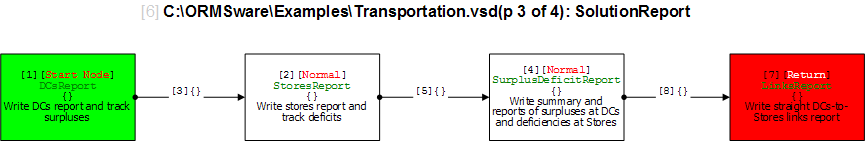

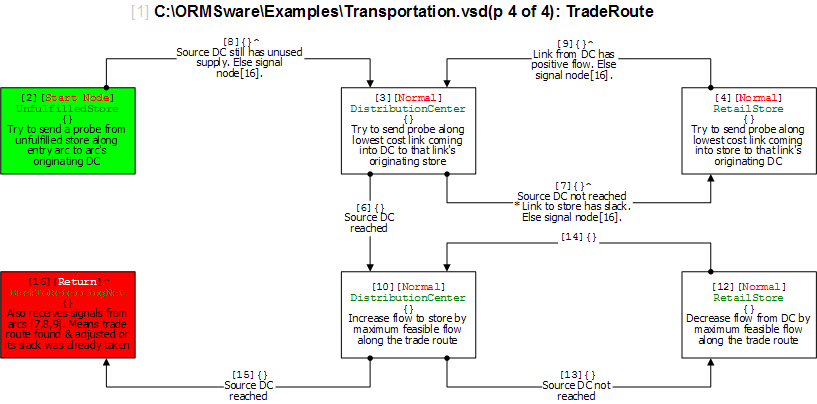

A mass merchandiser in UK wanted a model for minimizing weekly cost of shipping roughly 13 million cases of goods from 9 distribution centers (DCs) to 772 retail stores. I have used an approach here that is easily visualized and implemented through ORMSware to solve this routine business problem typically solved in other ways. This approach thrives on constraints so more can be easily added than the ones presented here. Pease note, however, that Kuhn-Tucker conditions for optimality is not checked in this fast algorithm. The approach starts with a quick solution (Initial Plan) achieved by sending "probes" simultaneously from every DC to every store it supplies. They reach their targets in ascending order of per-unit shipping costs, allocating all units available at their originating DCs, per the needs of their targets at the moment they reach the targets. If demand at every store can be met this way, a near-optimal answer will have been reached in a split-second. Chances are, however, that demands at some stores may not be fully met, requiring adjustment of Initial Plan to meet all demands at all stores. When DCs-to-stores flows of units in Initial Plan are changed to meet deficits, total cost increases. Our objective then is to minimize this increase while making the solution feasible (i.e. making sure that all demands at all stores are met without exceeding the original supplies at each DC). The solution also had to meet another requirement. Each store could only be supplied from 3 DCs closest to it. This restriction meant surplus DCs could not directly supply all deficient stores (else, Initial Plan probes would have achieved a near-optimal solution). The supply restriction was satisfied by systematically increasing and decreasing flows from DCs to stores through minimum cost trades, in just a few iterations, in seconds. This report is mostly about morphing the infeasible Initial Plan into feasible minimum cost plan by trading flow allocations. A dynamic program (mathematical optimization) is used to find multiple solutions simultaneously during each major iteration and picking minimum cost trade routes. ORMSware makes it easy to visualize and implement this approach and also easy for virtually anyone interested to understand how it works.

Develop a program for minimizing transportation costs of distributing 13 million cases of goods weekly from 9 distribution centers (DCs) to 772 retail stores of a retail chain. The program should be easily scalable and expandable to meet changing business conditions. The distribution plan must accommodate the following conditions and requirements:

This is a common linear programming problem with a special structure that is familiar to Operations Research analysts. A software developer contacted me after attempting to solve this problem by explicitly evaluating the costs of all possible combinations of shipping x units from y DCs to z stores. His inquiry and his approach for minimizing total cost are posted here. The retailer's weekly distribution requirements are posted here. The programmer's routine ran forever without producing answers because total supply of 13 million cases, 9 DCs, 772 stores, and 2316 permissible supply links made evaluating all allowable possibilities indiscriminately through exhaustive enumeration virtually impossible. Within the larger logistics planning picture of a big retail chain, solution to such a transportation problem needs to execute in just seconds. The speed of the approach presented here is not due to ORMSware or the computer used but due to Operations Research/Management Science. ORMSware simply makes programming the algorithm from scratch easy and highly reliable because the logic is visual, interesting, and easily extendable to impose more constraints as needed.

Here is a summary of the answers to the actual problem and links to the results files. Total cost column values reflect UK currency. Explanation of the approach used to solve the problem is provided using a small example further down, below these actual results tables. |